Services we Offer:

CNC Machining:

We offer in house CNC machining services in all alloys, with 3 axis vertical, 3 + 2 axis indexing; and full 5 axis high speed machining. Machine programming is done with GIBBS Cam utilizing direct CAD imports, and virtual tool path validation on screen prior to sending any file to the machining center. Advanced tool paths are created using integrated Volumill software dramatically reducing cycle time and increasing tool life. State-of-the-Art on machine probing is used for Cutter set up; wear monitoring; part set up; and in process validations. Benefits are reduced costs, increased accuracy, and reduced lead times

Click here to learn more

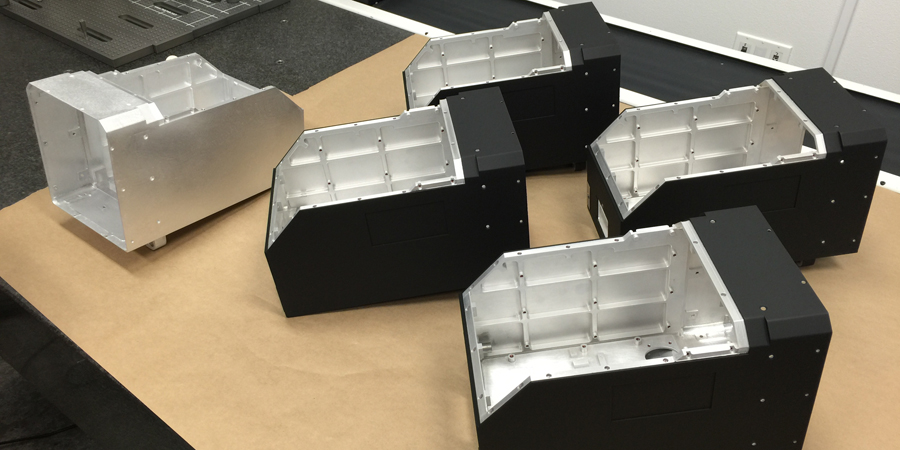

Aluminum Brazed Assemblies:

With over 35 years experience in the design and manufacturing of complex CNC machined and brazed assemblies we offer the in house control of the critical processes. CAD solids are used to model the fit, form, and function to validate our customer's designs prior to release to manufacturing. Our subcontract braze partners are closely monitored to assure compliance with applicable specifications and quality requirements.Click here to learn more

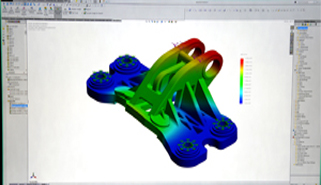

CAD Design Review:

. Our designers have over 35 years experience with design of complex aluminum brazed assemblies in both Salt Bath and Vacuum Brazed configurations. Our experience spans the range of single CNC machined components to complex assemblies. We perform tolerance analysis; and other reviews as needed to assure a high degree of design validation while still in CAD saving cost and lead time. Our in house processes support customer's DPD / MBD requirements by validating back to the Authority Dataset for any file translations.

Precision Inspection:

Inspection processes range from manual inspection using various gauging on surface plates to Solid model CAD based DCC CMM automated inspection in a climate controlled lab environment. First article inspections, in process, and final inspections are conducted and documented. Dimensional reports can be provided in various formats, including AS9102 when required. Subcontract inspection, or inspection programming services can be provided to support customer requirements based on the latest version of PC-DMIS CAD software.

GTAW / GMAW Welding:

Welded assemblies are created using MIG and TIG in steels, stainless, and aluminum alloys.