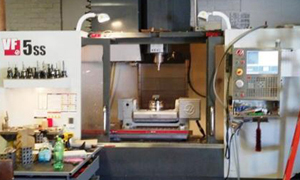

CNC Machining:

Equipped for Speed, Accuracy, and Efficiency:

We have learned over the years that the lowest price is often not the best value solution. Our philosophy is to equip each department with the most advanced tools and training so all processes efficiently meet requirements. This ensures on-time quality, customer satisfaction and the best value solution. Our machines are equipped with tool setting probes, high capacity super speed tool carousels, Renishaw work offset probes, wireless probing, high horsepower / high RPM spindles, high pressure through spindle coolant, programmable coolant nozzles, auto air blast nozzles, complete bed precision foundation system by Chick, Zero point tooling systems by 5th Axis, vacuum fixtures, trunnion tables which allow 4th and 5th axis indexing or true 5 axis machining, precision balanced tool holding systems and powRgrip® insertion system by Rego-Fix. All leading to one end: providing our customers with a low cost, quick delivery solution, while maintaining the highest quality and compliance to all specifications. Marrying high technology with a broad depth of experience is a winning solution for our customers.

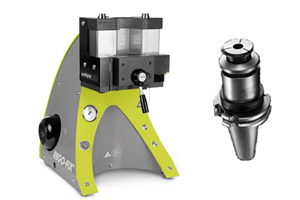

Rego-Fix Tool Systems:

Swiss precision, the powRgrip® system offers an inherently balanced tool holding system similar to thermal shrinkfit systems, but with greatly increased clamping force, a smaller run-out, increased tool life,, and faster tool changes all without the heat. Problems associated with overheating and induced thermal stresses are completely avoided.

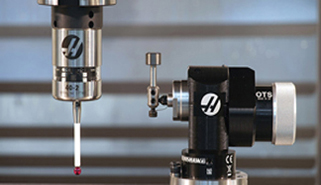

On Machine Probing Systems:

Using the latest wireless strain gauge based probing systems from Renshaw, machine set ups are completed quickly and accurately. The flexibility provided by these systems allows for support of customer schedule changes by minimizing the time and costs associated with set up changes and production run breaks for small lot quick turn needs.

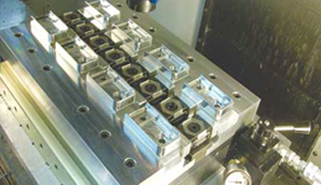

Rapid Accurate Set Up:

The point of all the technology is providing value to the customer. We never lose sight of this key point. Close tolerance, quick deploying and repeatable setups ensure consistent quality, speed and reduced costs.